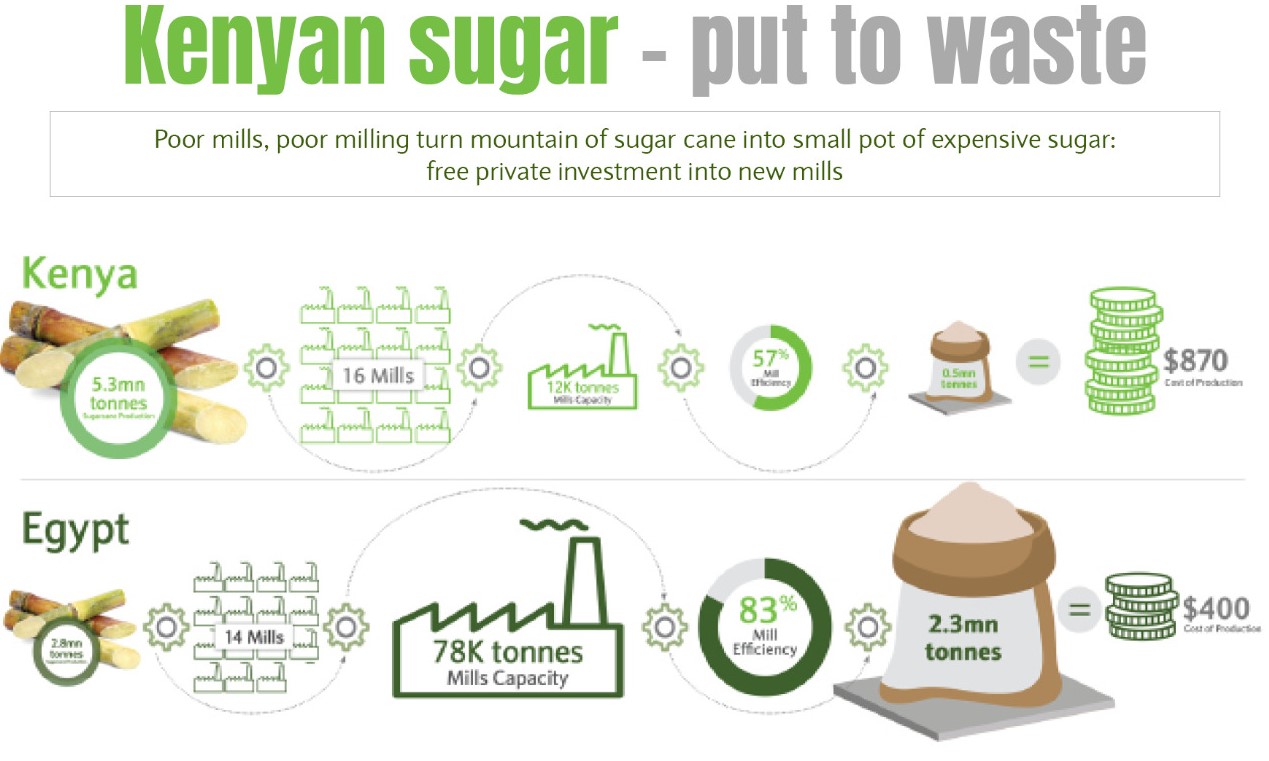

Kenya produces around 5.3m tonnes of sugarcane a year, almost twice Egypt’s production.

But the sugar processing is 10x more efficient in Egypt, producing 2.3m tonnes of sugar from 2.8m tonnes of sugar cane.

In Kenya, millers produce 0.5m tonnes of sugar from 5.3m tonnes of sugarcane.

The country’s total sugarcane crushing capacity is 12,000 tonnes per day, but its mills only crush 57.5 per cent of this.

By contrast, other countries have higher capacity and greater mill utilisation. Egypt has a crushing capacity of 78,400 tonnes per day and mill utilisation of 83.2 per cent. Pakistan has a crushing capacity of 361,300 tonnes per day and mill utilisation of 91 per cent.

A key reason Kenyan mills are underperforming is because they are burdened by obsolete milling technology. Experts point out that a number of government mills have not had the proper annual out of crop maintenance for more than three years. That annual maintenance can cost between Ksh 0.6 to 1 bn per annum. When factories are cash strapped managers just keep them running as best they can. Thus overall efficiency keeps falling.

Other mill inefficiencies include mismanagement that has led to the accruing of huge debts to farmers, to the tune of Sh2.6bn. As a result many farmers lack funds to do another round of planting contributing to low sugarcane delivery to the mills. Other farmers however opt to then deliver to private mills which has fewer cases of debt accumulation compared to their government counterparts.

The sum is sugar that is twice as expensive to produce as the global average, despite ideal growing conditions.